Description

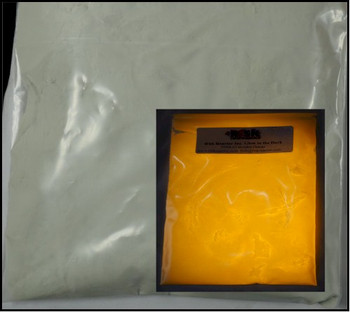

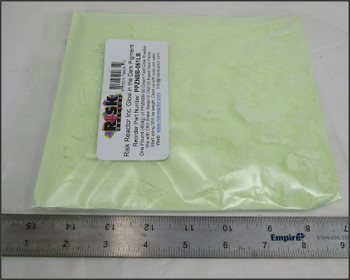

Reordering part number PPSB-061LB one pound of the yellowish green coating additive.

Risk Reactor Inc.'s glow in the dark series of photo luminescent pigment were developed for your luminous project. Simply add the powder to your clear medium and it will glow after being charged with light.

Our team of chemists have developed the best performing phosphorescent powder on the market. PPSB-061LB this pigment, along with our PPSB-10 is one of the strongest pigments on the market today. Both of these can glow for more than 100 hours on a single charge and are rechargeable. Our PPSB-06 Invisible Yellow Green phosphorescent pigment was developed to go into non water based mediums only. You can use the pigment in water based medium for a short period of time, such as mixing and then using.

Phosphorescent pigment is the basic building block for material that glows in the dark. It works by absorbing ambient light and then re-emitting it in the visible spectrum. This process can be repeated an infinite amount of times. The color visible in regular light is an off white and it will glow a vibrant Yellow Green in the dark. This "change" of color is why we refer to it as invisible. You can mix this pigment into any clear medium such as glue, paint, caulking, wax, clay, gel candles, liquid nails, silicone, urethane, you name it. Some call this a natural glow powder but we call them invisible. It is usually an off white or light in color. Most often they appear off-white in normal daylight then glows either green, aqua, blue, purple or white in the dark. If mixed at a low loading, 10% instead of 30% then it can appear invisible or transparent i the coating.

Benefits of Risk Reactor's PPSB-061LB Invisible Yellow Green Pigment:

Glow for more than 100 hours on a single charge!

Easy to work with!

Multi-Purpose Use

Long afterglow lasting pigment!

Product can last more than 15 years, unlike conventional pigment!

Just about any light will charge it!

Glows a strong Yellow Green!

20-30 Years of Glowing time.

Non-radioactive!

Safe and non-toxic!

Unique Colors that glow in the dark.

Can be used with just about any non-aqueous medium!

Best on the Market

The PPSB-061LB natural glow powder Used In:

Clock & watch dials, paint, electronic instrument dial pads, poly urethane, home appliances, lighting apparatus and switches, exit signs, emergency signage and low level lighting escape systems (Egress Systems), aircraft and automobile dials and instrument panels, fireman's equipment, traffic signs & high visibility signs, fishing equipment, military applications, outdoor path marking, camping equipment, textile printing and textile fibers, writing & printing inks, You can use this product anywhere a long afterglow and/or light fastness is needed.

Glow in the Dark PPSB-061LB Technical Information:

Appearance: Light-Yellow Powder/No Order

Melting Point: Dissociates 1200 C

Excitation Energy: 200-450 nm

Emission Wavelength: 523 nm

Vapor Pressure: N/AP

Vapor Density: N/AP

Solubility In Water: soluble

Weight Per Cube Meter: 3.0-3.6

Flammability Class: N/AP

Chemical Name: Alkaline Earth Metal Oxide Europium Doped.

Extinguishing Media: Water

Specific Gravity: 3.0-3.6

Evaporation Rate: N/AP

pH (% in water): N/AP

Flash Point: N/AP

Auto-Ignition Temp: N/AP.

Note: This pigment should not be exposed to any water including humidity. If it does, it will eventually breakdown and you will loose about 20% of the glowing capacity. Store in a cool dry place.

Glow Time Chart Measured in mcd/m2

The afterglow brightness is measured under D65 standard light source excited by 1000 lux for 10 minutes. The excitation wavelength is 253.7 nm. The instrument to determine brightness LS-100. As a general rule, the larger the particle size the greater and longer the glow. The threshold of the human eye to detect light is .32 mcd/m2 with a dark adapted eye.

How to Use:

This product is easy to work with. Simply mix it with a clear medium such as clear paint, clear glue, clear wax, etc. and you will have a glowing material! Follow the guidelines below to ensure you maximize the glowing effectiveness of our product.

- More powder, higher percentage will produce brighter, longer glow.

- Use a white, or light color as a background for best results. Any color other than white will diminish glow.

- Use the clearest vehicle possible. Any pigment in the vehicle will decrease the brightness and length of glow.

- The thicker the layer of Glow Powder will produce longer and brighter up to a point.

- Try to prevent moisture in the manufacturing process.

- Do not use vehicle with high acidity and if you do keep your pot life short.

- Do not grind the Glow Powder, it will destroy the crystal structure and therefore decrease luminosity.

- The larger the particle size of the Glow Powder the greater the glow.

- Ratio of Glow Powder to medium is from 10% to 50% by weight depending on application and manufacture process. Best to start with 30% and move and down depending on cost, manufacturing process, and other factors that are unique to your application.

|

Time |

CP2-06 Yellow Green Glow Paint. |

|

0 minutes |

17310 |

|

.5 minutes |

4658 |

|

1 minutes |

3122 |

|

2 minutes |

1925 |

|

3 minutes |

1403 |

|

4 minutes |

1102 |

|

5 minutes |

911 |

|

6 minutes |

774 |

|

7 minutes |

670 |

|

8 minutes |

590 |

|

9 minutes |

529 |

|

10 minutes |

478 |

|

20 minutes |

237 |

|

30 minutes |

150 |

|

40 minutes |

109 |

|

50 minutes |

84 |

|

1 hour |

67 |

|

2 hour |

29 |

|

3 hour |

19 |

|

4 hour |

13 |

|

5 hour |

10 |

|

6 hour |

8 |

|

7 hour |

7 |

|

8 hour |

5 |

|

9 hour |

3 |

|

10 hour |

6 |

|

11 hour |

3 |

|

12 hour |

4 |

|

Emission Peak |

523 nm |

|

After Glow Time |

6800 minutes |